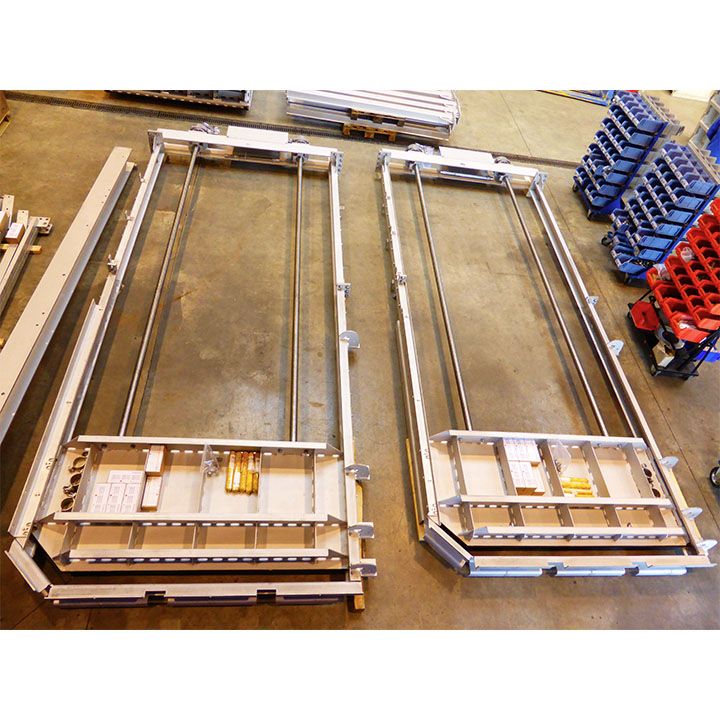

Stainless steel channel penstock, 3-sided sealing

Opening size 150 × 150 mm bis 3500 × 3500 mm

- Pressure stage on front or rear side possible

- Pressure stage corresponds to the panel height

Materials

- Frame and panel: stainless steel 1.4301 (SS304) / 1.4404 (SS316L) / 1.4410 (A182 F53) / 1.4462 (A182 F51) / 1.4539 (904L) / steel 1.0038 (A36-hot-dip galvanized)

- Seal: EPDM (wastewater- and UV-resistant) or NBR

- Spindle: stainless steel 1.4301 (SS304) / 1.4404 (SS316L) / 1.4410 (A182 F53) / 1.4462 (A182 F51) / 1.4539 (904L) / steel 1.0038(A36-hot-dip galvanized)

- Spindle nut: GC-CuSn 12, seawater resistant bronze

Other materials available on request.

Leak tightness class

- Leak rate better than DIN EN 19569, Part 4, Table 1:

- Pressure on front side: max. 1 % from 0.05 to 0.1 l · s-1 · m-1 (leak tightness class 3)

- Pressure on rear side: max. 5 % from 0.1 to 0.3 l · s-1 · m-1 (leak tightness class 2)

Actuation of the penstock by:

- Stainless steel handwheel on transverse yoke

- Lateral actuation with gearbox with BÜSCH stainless steel bevel gearbox with stainless steel handwheel or stainless steel crank handle

- BÜSCH all-in-one control key via square cap

- BÜSCH MOBITORQ mobile electric actuator via square cap

- BEA©servo stainless steel electric actuator assembled on transverse yoke, optional with BÜSCH weather protection roof

- Pneumatic actuator assembled on transverse yoke

- Hydraulic actuator assembled on transverse yoke

- E-Actuator

All actuator options available as a complete package.

Individual sizes are possible at any time on request.

Please contact our customer service via contact form.